VNIS portfolio

VNIS's portfolio includes the entire range of major field crops, as well as niche crops. Sunflower takes a significant share in it. The breeding company's portfolio includes more than 20 hybrids, 9 of which are commercially available (with a growing season of 80 to 115 days). There are both hybrids for classical technology and those with resistance to tribenuron-methyl and Euro-Lightning.

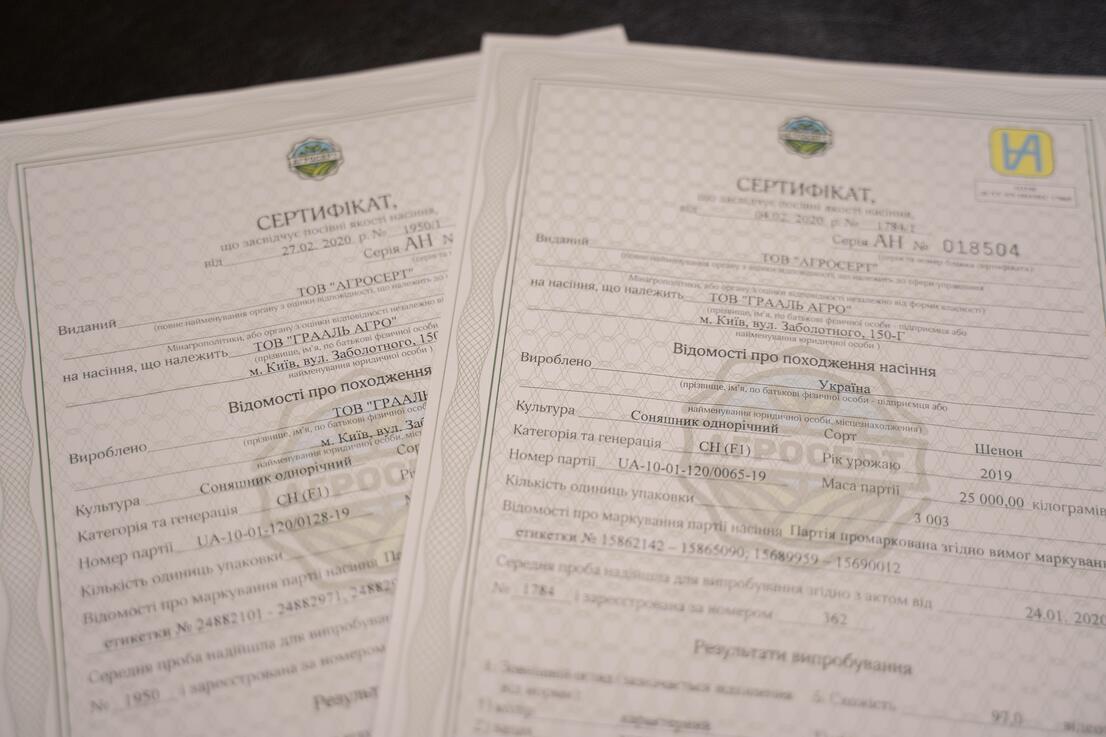

Seed quality control: from field to bag

The first task in the seed production process is to grow a high-quality seed crop. Quality control is carried out at all stages, starting with hybridization sites.

According to Vladimir Skoryk, VNIS' leading agronomist and candidate of agricultural sciences, quality control begins in the field. Before harvesting the hybridization plot, VNIS specialists take average samples from each field. Each time they check for germination and germination energy. This way, they have a preliminary idea of what to expect from each plot. In the future, it's the same. From harvesting and in the process of processing, to the finished product in a bag directly at the seed plant itself. Quality control is carried out at each stage of processing: primary cleaning, secondary cleaning, vibro-pneumatic cleaning, photo separator, chemical treatment, packaging. These tests are performed by the seed plant's laboratory, and there is also internal control.

According to the VNIS agronomist, all the company's seeds offered to producers meet the requirements of the State Standard of Ukraine. But there are also internal standards that are somewhat higher than the DSTU tolerances. That's why control tests are performed at all stages of production to comply with internal standards.

“For example, if our germination rate for a grain group according to DSTU cannot be less than 92%, then we produce at least 94%. As for corn, the DSTU requires at least 92% germination, so we have 94-95% germination. And for sunflower, the standard is 85%, while our tolerances are 93-95%,” emphasizes Volodymyr Skoryk.

According to him, the internal quality control of seed is carried out separately for each batch of seeds in the testing laboratories Agrogen-Novo and Agrogenesis. These laboratories are accredited according to ISO 17025:2017. They analyze such indicators as the level of hybridity (which must be at least 99%), seed purity, weight of 1000 seeds, germination energy, germination rate, moisture content, and the presence or absence of infectious agents. And finally, when the seed batch has already been formed, the inspector, an authorized person, takes samples on the basis of which certification is carried out by accredited laboratories.

As for the finalization of the seeds at the plant, the main goal is to achieve maximum uniformity of the finished seeds in terms of size, specific gravity, germination and germination energy.

“This is necessary in order to achieve the specified density that the producer wants to have when sowing the seeds, which is now used for sunflower and other crops. Moreover, the work aimed at this goal starts from the seed field. We have already mentioned that samples are analyzed at all stages of the growing season, and before harvesting as well. So we can already get a rough idea of the seed yield from the field, but the harvesting stage is also important. For sunflower, for example, it is very important to adjust the combine. It is necessary to set the minimum speed of the threshing drum and increase the under-drum clearances. This ensures minimal damage to the seeds during harvesting. Accordingly, we have the maximum yield of ready-made seeds from the heap, and at the same time their germination does not decrease,” says Volodymyr Skoryk.

Maintaining quality on the way to farmers

Then the “baton” for preserving the genetic potential of seeds and improving their quality is passed to the seed plant. VNIS cooperates with several domestic enterprises in different regions of the country. For example, for corn, a “short way” from the field to the plant is a very important factor. But for sunflower, it can be somewhat longer. Therefore, VNIS processes sunflower seeds mainly at Agrocomplex-2012 LLC, whose plant is located in Zaporizhzhia region.

According to Vasyl Chornovil, the company's CEO, the plant is set up to process sunflower seeds.

Primary cleaning takes place on a Delta 146 Cleaner machine from Cimbria, with a production capacity of 10-15 tons per hour. In fact, most of the equipment at the plant is from this well-known Danish manufacturer.

The air-grid separator separates coarse and large impurities. The main fraction is separated, which is then processed further. It passes along a line, through triplets, where it is sorted by length - long and short impurities are separated. Then it goes to the gravity table, where it is sorted by specific gravity.

“For our seeds, we do not take a fraction smaller than 3.0 mm in diameter. That is, all the seeds that are used for further processing and bagging are always of a fraction of more than 3 mm,” says Volodymyr Skoryk, VNIS's leading agronomist.

And after the initial cleaning, the seeds go to the bunker, from which they are fed to the dryer.

“Sunflower seeds require a gentle, “soft” drying regime. That is why we remove no more than 4% moisture in 1 cycle (there are several such cycles: the grain is dried, then cooled, then fed back for drying, and thus, in the process of circulation, it is gradually dried to the required level). At the same time, the temperature of the air supplied to the dryer does not exceed 30°C, but it is mostly 25-27°C,” says the company's director.

Storage and processing of seeds

After drying, the material is fed into long-term storage bins with active ventilation, where it is periodically blown to prevent condensation. Here, the seeds are stored under temperature control. This is how the process of biological ripening takes place - the grain “plunges” into a state of rest, and when it reaches the required indicators for sowing, it is put into processing. This means secondary cleaning, calibration, dressing, and finally packaging.

If necessary, a photo-separator is used to remove seeds with atypical colors and injuries using infrared detectors.

“The photo-separator removes hard-to-separate impurities that cannot be separated by classical machines,” says Vasyl Chornovol.

Sunflower seeds from VNIS are treated with carbendazim and metalaxyl. According to Volodymyr Skoryk, the company's agronomist, this treatment is aimed at preventing diseases such as gray and white rot and downy mildew.

“Additionally, the seeds are treated with growth stimulants. In addition, we use dyes produced by FerraraAgro. They have proven to be very good for seed treatment, giving a uniform coating of each seed,” he adds.

Before loading into the storage hopper, quality control is mandatory. The laboratory determines the purity and weight of 1000 seeds. Based on the latest data, the average is determined and the weight of the sowing unit is set, which is indicated on the package. In any case, according to the agronomist, VNIS tries to ensure that the weight of 1000 seeds is at least 55 grams.

“Sunflower seeds are essentially divided into 2 fractions: standard and extra. In the standard fraction, the weight of a thousand is 55-62 grams (depending on the hybrid). If the weight of 1000 seeds is 64 grams and above, this is the extra fraction, and for our hybrids it is either 65 grams or 70 grams,” the agronomist clarifies.

The plant's laboratory also controls humidity during the packaging process. After packaging, the weight of the bags and the correct labeling are monitored. Of course, samples are also taken from each batch to be analyzed for certification.

Packaging and labeling of seeds

One of the factors that preserves the quality of the seeds after such painstaking work on them is the bags in which they reach the farmers directly. According to Victoria Galat, VNIS sales manager, the company's seeds are packaged in three-layer high-quality paper bags from the well-known manufacturer MondiBags. This allows the seeds to breathe and retain their sowing qualities for a long time, despite changes in temperature and moisture, until sowing.

Ms. Kovalenko gave some advice on what farmers should pay attention to when purchasing VNIS seed.

First of all, it is a state standard label. It must be glossy and contain the following information:

- manufacturer;

- culture

- name of the hybrid;

- number of seeds in one sowing unit;

- date of packing of seeds;

- weight of the bag;

- what the seeds are treated with;

- batch number, which must correspond to the one specified in the certificate;

- individual label number, which is issued directly by the State Center for Certification and Expertise of Agricultural Products.

“To check this data, you can go directly to the website of the State Center for Certification and Expertise of Agricultural Products and get all the information about the hybrid, producer, batch number, certificate, etc. The label should also have a hologram developed by VNIS on an individual order. It contains the logo of our company. The next thing we pay attention to is the QR code. Scanning it automatically takes you to the company's website - to the section that describes how to protect yourself from counterfeiting,” says Viktoriia Galat.

You should also familiarize yourself with the rest of the label, which contains recommendations for seed storage and cultivation technology.

“I would also like to draw your attention to the fact that the bags of sunflower and corn seeds of the 2020 harvest are made in a combination of white and green corporate colors, with the corresponding image of the crop you purchased. And the bottom of the bag, which is made in yellow, contains the entire line of hybrids, with a mark next to the name of the hybrid you purchased. It corresponds to the seeds in the bag and the name of the hybrid on the label,” adds Ms. Viktoriia.

Choosing quality seeds

Seed breeders and producers invest a lot of effort and money to ensure that consumers receive high-quality seed and grow the crops that the developers of hybrids or varieties have “programmed”. Therefore, the right choice of seeds by an agrarian is like a successful conclusion to a long story. Although... If you think about it, it is rather the beginning of the next one - in which all the efforts made should be realized in a good harvest and the prosperity it will bring.

Choose a country

Choose a country